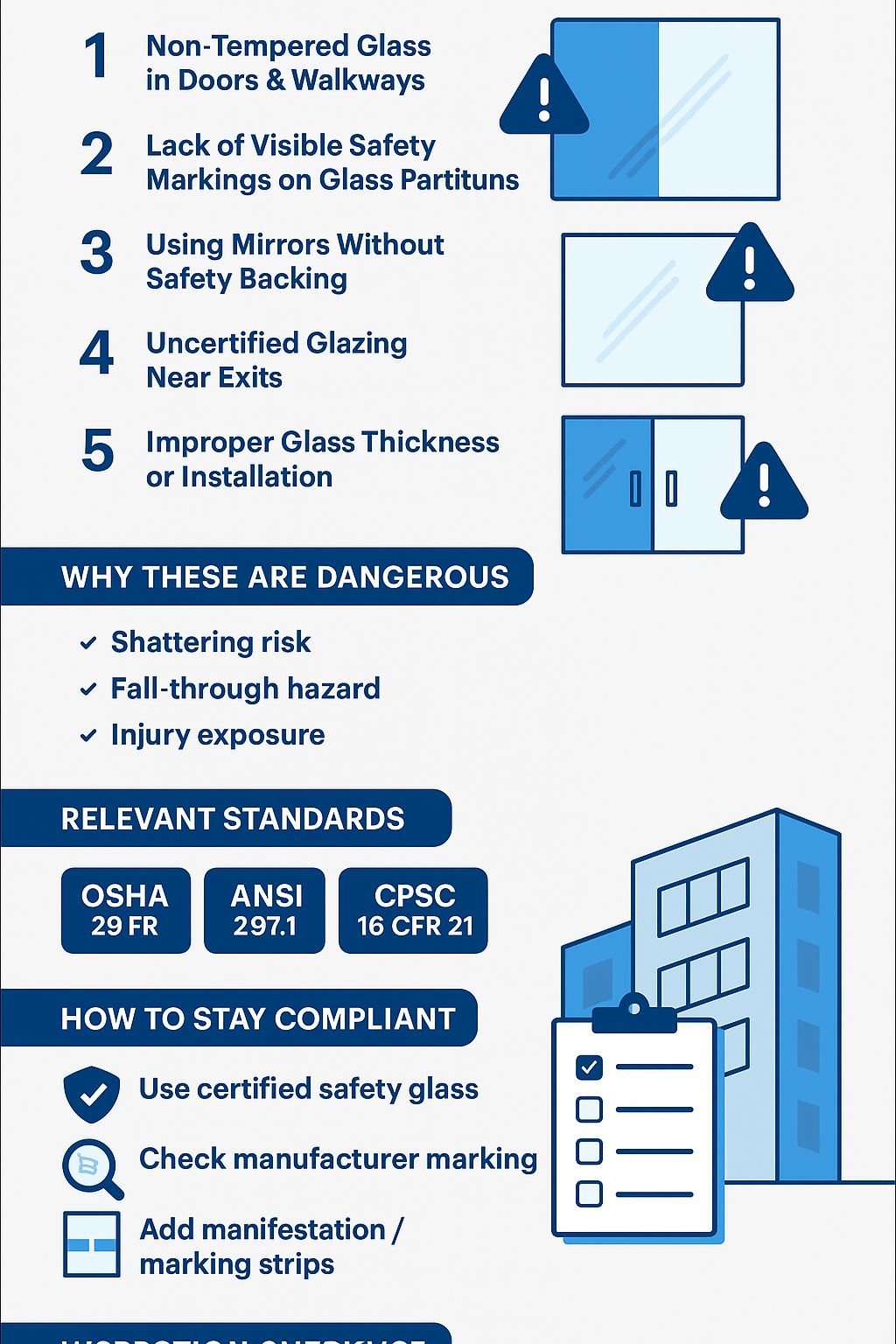

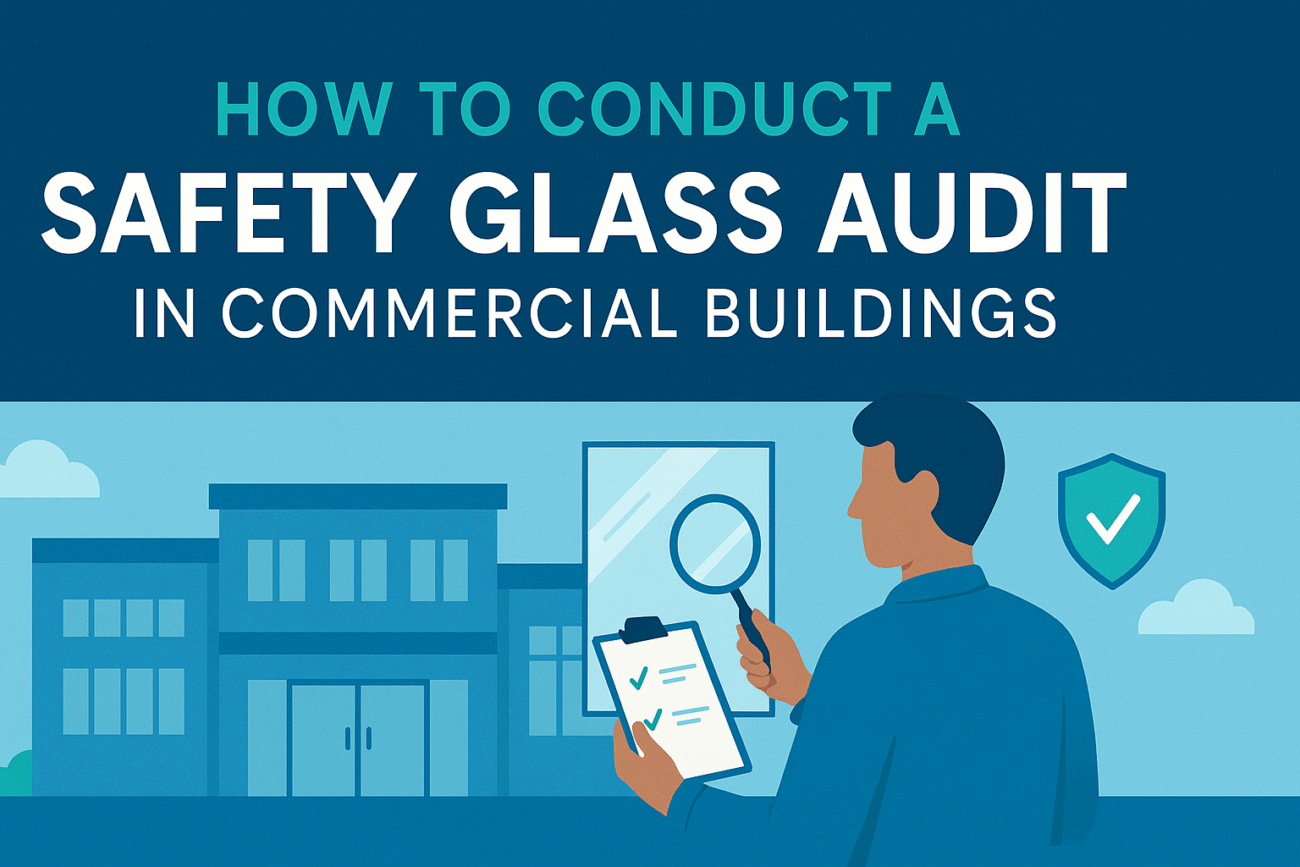

Common Safety Glass Violations in Commercial Buildings and How to Avoid Them

Even well-designed commercial spaces can fail glazing safety compliance. From untempered doors to missing manifestation markings, small oversights can cause major hazards and OSHA violations. Here’s how to recognize the most common issues — and prevent them before inspection.

1. Non-Tempered Glass in Doors and Walkways

A frequent code violation is using standard annealed glass instead of safety glass in entryways or near walking paths. According to ANSI Z97.1 and CPSC 16 CFR 1201, all glazing in “hazardous locations” must be tempered or laminated safety glass to protect people from impact injuries.

2. Missing Safety Markings on Clear Partitions

Floor-to-ceiling glass partitions without visible markings are another violation. OSHA requires clear manifestation — such as decals or frosting bands — at eye and waist level to make the glass visible and prevent accidental collisions.

3. Mirrors Without Safety Backing

In gyms, studios, and retail spaces, mirrors must include safety backing film. Without it, broken mirror glass can detach and fall, causing serious harm. ANSI-compliant mirrors use a protective vinyl film that holds fragments in place if breakage occurs.

4. Uncertified Glass Near Exits and Stairways

OSHA 29 CFR 1910.37 mandates impact-resistant glass near exits and escape routes. Using uncertified glazing here not only violates safety codes but also jeopardizes evacuation safety during an emergency.

Always confirm that glass in these areas bears an etched ANSI Z97.1 or CPSC 16 CFR 1201 compliance mark.

5. Incorrect Glass Thickness or Support

Using undersized or unsupported glass panes is another common infraction. Large glass panels need the correct thickness and secure edge support to prevent stress fractures or collapse.

Consult your supplier or structural engineer for proper thickness, load ratings, and fixing methods before installation.

Relevant Standards and Codes

- OSHA 29 CFR 1910 — General workplace safety for glazing materials

- ANSI Z97.1 — Safety glazing requirements for architectural applications

- CPSC 16 CFR 1201 — Federal regulation governing impact-resistant glazing

How to Avoid These Violations

- Use certified tempered or laminated glass in all impact-prone areas

- Ensure mirrors include a safety backing film

- Apply visible markings to clear partitions and doors

- Check for ANSI/CPSC etched markings before installation

- Verify glass thickness and fixing method per manufacturer data

For a helpful overview of safety glass specifications and compliance standards, see

GlassHelp’s tempered glass guide,

which outlines impact safety classifications and correct usage in architectural glazing.

Leave a comment