How to Conduct a Safety Glass Audit in Commercial Buildings

Regular audits of glass installations are vital for workplace safety and legal compliance. Over time, even well-installed glazing can become non-compliant due to unnoticed damage, outdated markings, or improper replacements. This guide outlines a professional approach to ensure every pane meets current standards.

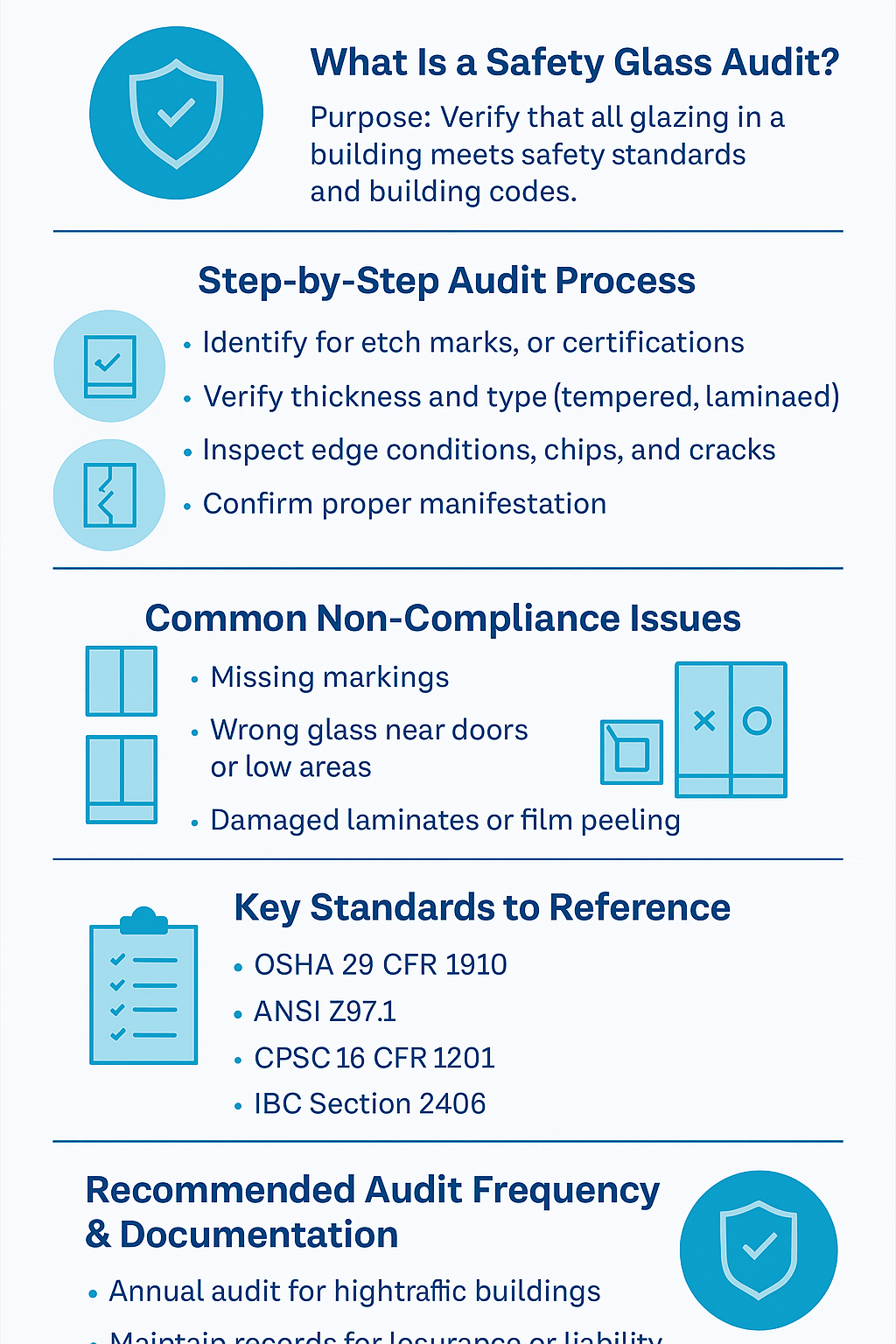

What Is a Safety Glass Audit?

A safety glass audit is a structured inspection process carried out to confirm that all glazing in a commercial facility adheres to OSHA, ANSI Z97.1, and CPSC 16 CFR 1201 standards. It ensures the use of compliant, impact-safe glass types — protecting occupants and minimizing liability.

Step-by-Step Audit Process

- Identify all glazing locations: doors, partitions, windows, balustrades, and entrance areas.

- Check each pane for a visible safety mark or etched certification symbol.

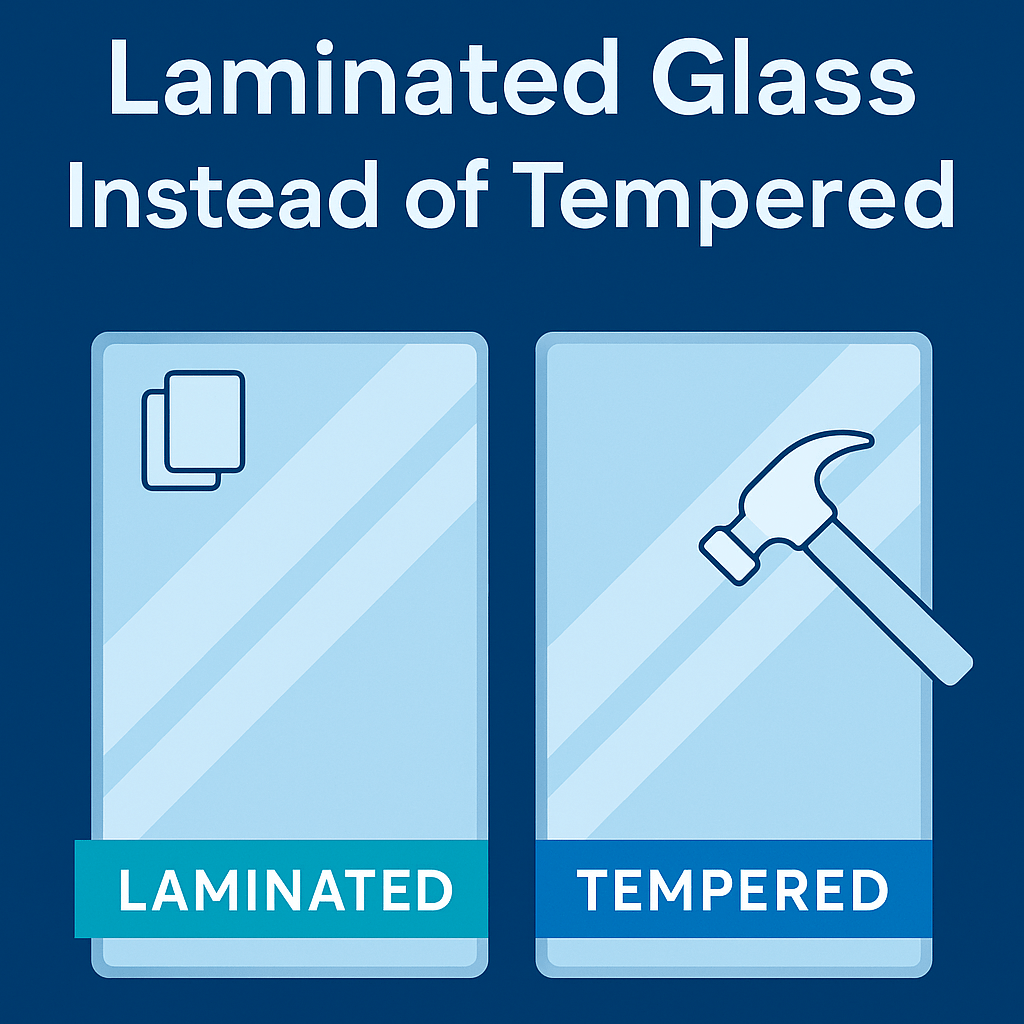

- Verify that glass type and thickness match the usage location (tempered or laminated).

- Inspect edges, corners, and surface for cracks, chips, or stress lines.

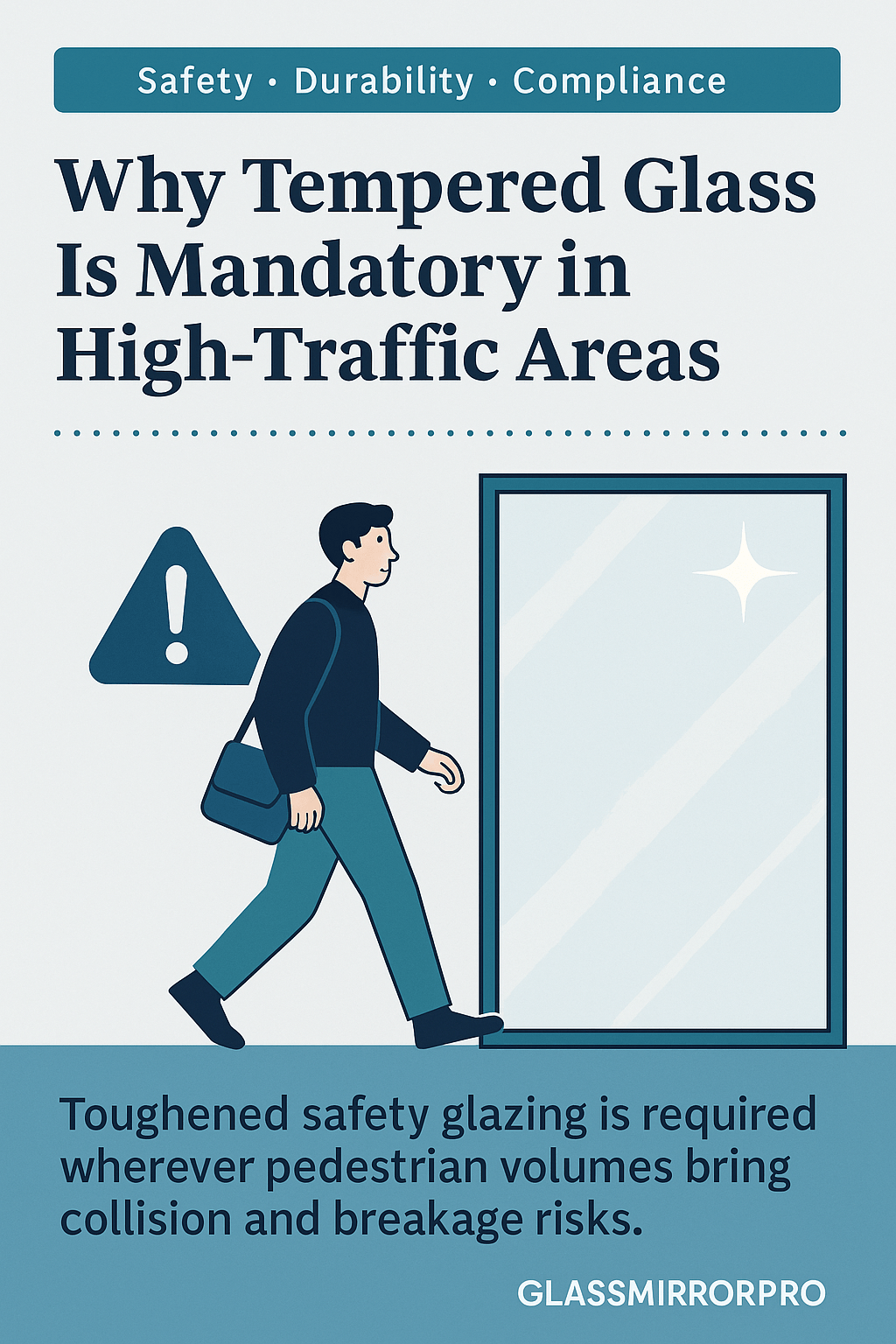

- Confirm that glass in pedestrian routes includes proper manifestation markings.

- Document findings with photographs and record any areas needing corrective action.

Common Non-Compliance Issues

- Missing or faded safety etch marks.

- Uncertified glass installed near doors or low-level areas.

- Improper replacements that do not match the original safety rating.

- Peeling safety backing on mirrors or laminated glass delamination.

- Cracked panels that have not been replaced.

Key Standards to Reference

Every audit should align with the latest recognized safety codes:

- OSHA 29 CFR 1910 — Workplace safety and glazing requirements.

- ANSI Z97.1 — Safety performance for architectural glazing materials.

- CPSC 16 CFR 1201 — Federal standard for consumer safety glazing.

- IBC Section 2406 — Locations where safety glass is mandatory.

Audit Frequency & Documentation

Conduct a full glass audit annually, or whenever a building undergoes renovation. Maintain detailed inspection records for insurance and compliance review. Most facility managers find it effective to integrate glass audits within broader safety inspections.

When to Replace or Upgrade Glass

Replace any glazing that lacks certification markings, shows damage, or fails compliance testing. Consider upgrading older installations with modern tempered or laminated safety glass to meet today’s codes and improve occupant safety.

Additional Resources

For detailed technical guidance on safety glass classifications and testing standards, refer to

GlassHelp’s comprehensive overview of tempered glass standards.

It’s a useful reference when comparing different safety categories during audits.

Leave a comment