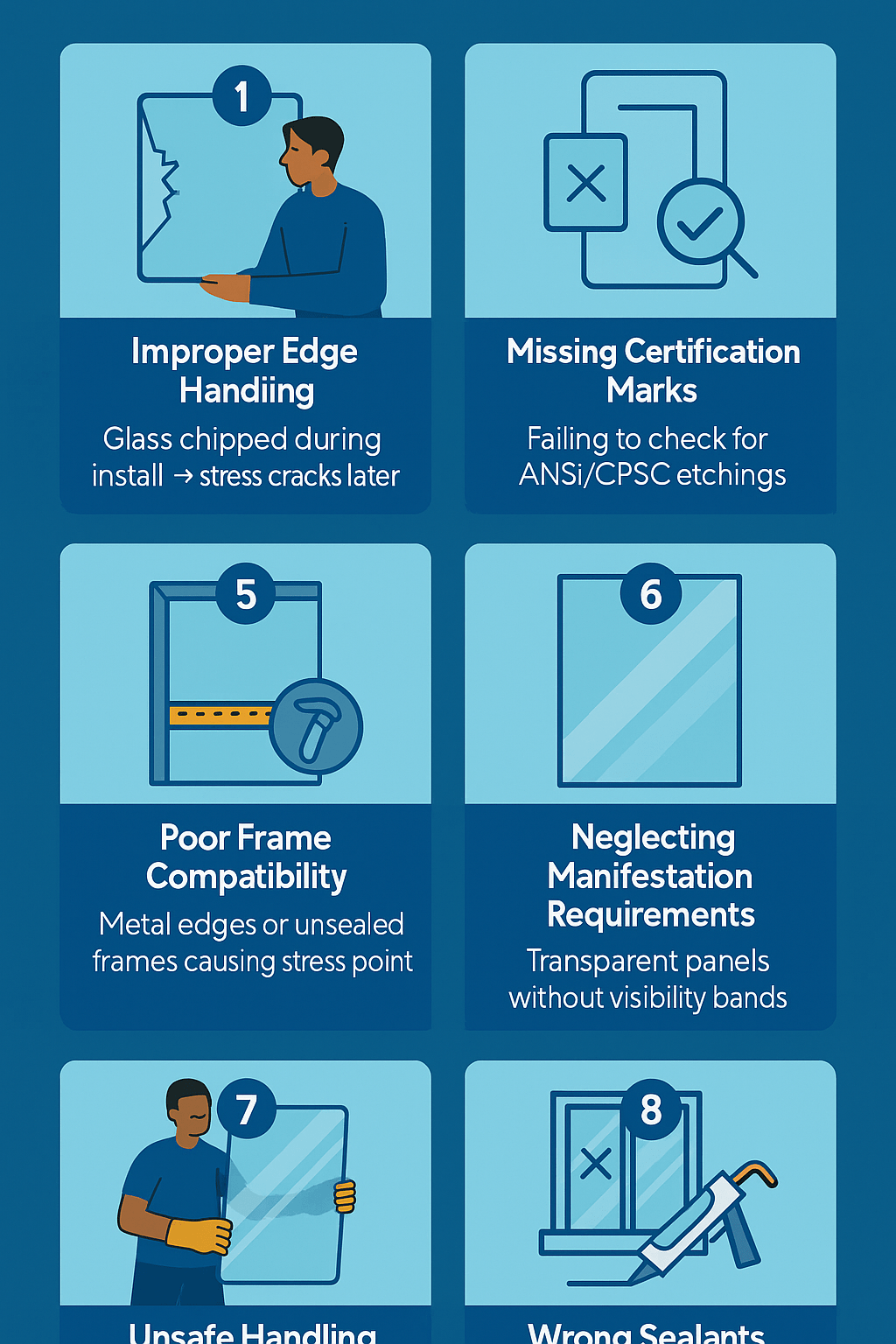

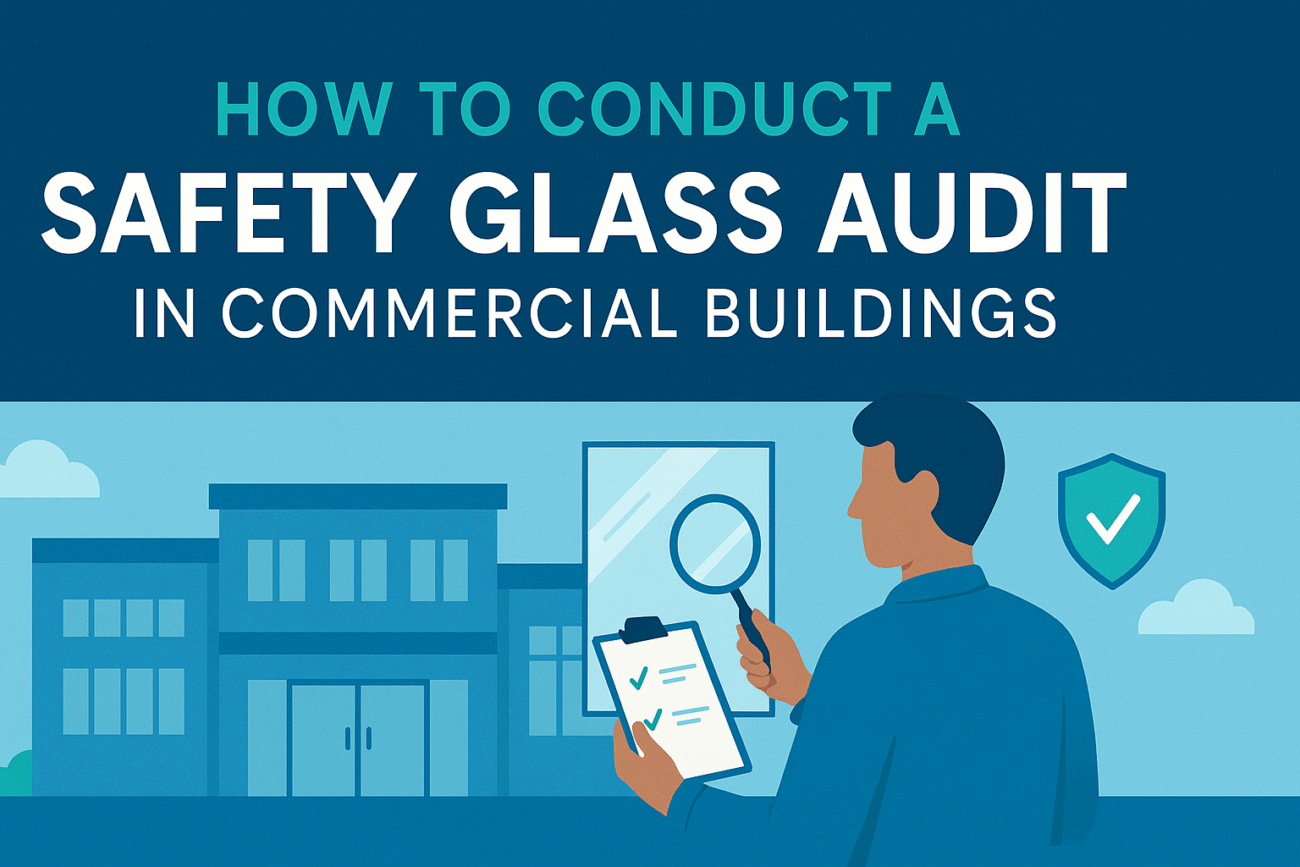

Top 10 Mistakes Contractors Make When Installing Safety Glass

Even experienced installers can make errors that compromise safety, code compliance, or long-term durability. These common mistakes often lead to injury risk, warranty voiding, or regulatory fines. Let’s address them — and show you how to avoid them.

1. Improper Edge Handling

Chipping or rough handling of glass edges during installation introduces stress points — a leading cause of spontaneous failure later. Always carry panels upright, avoid metal contact, and use proper edge protection.

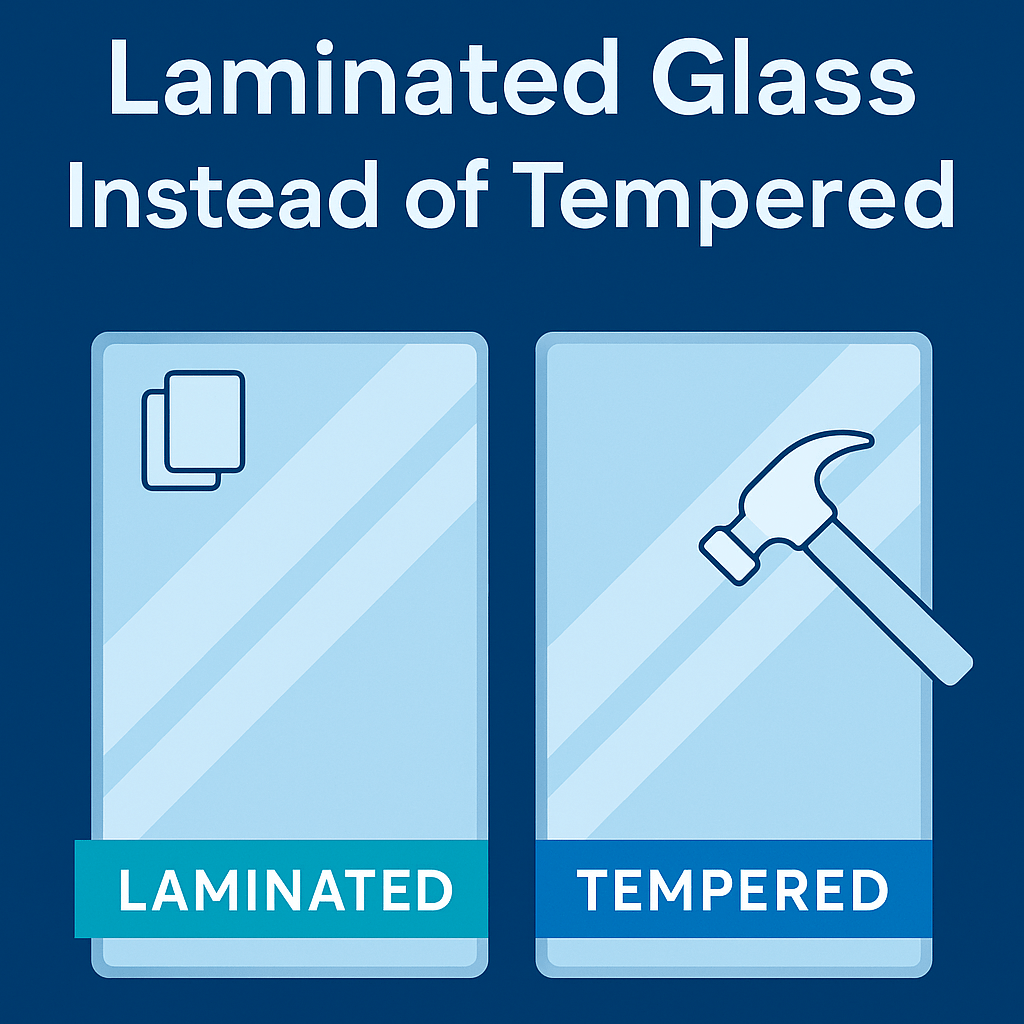

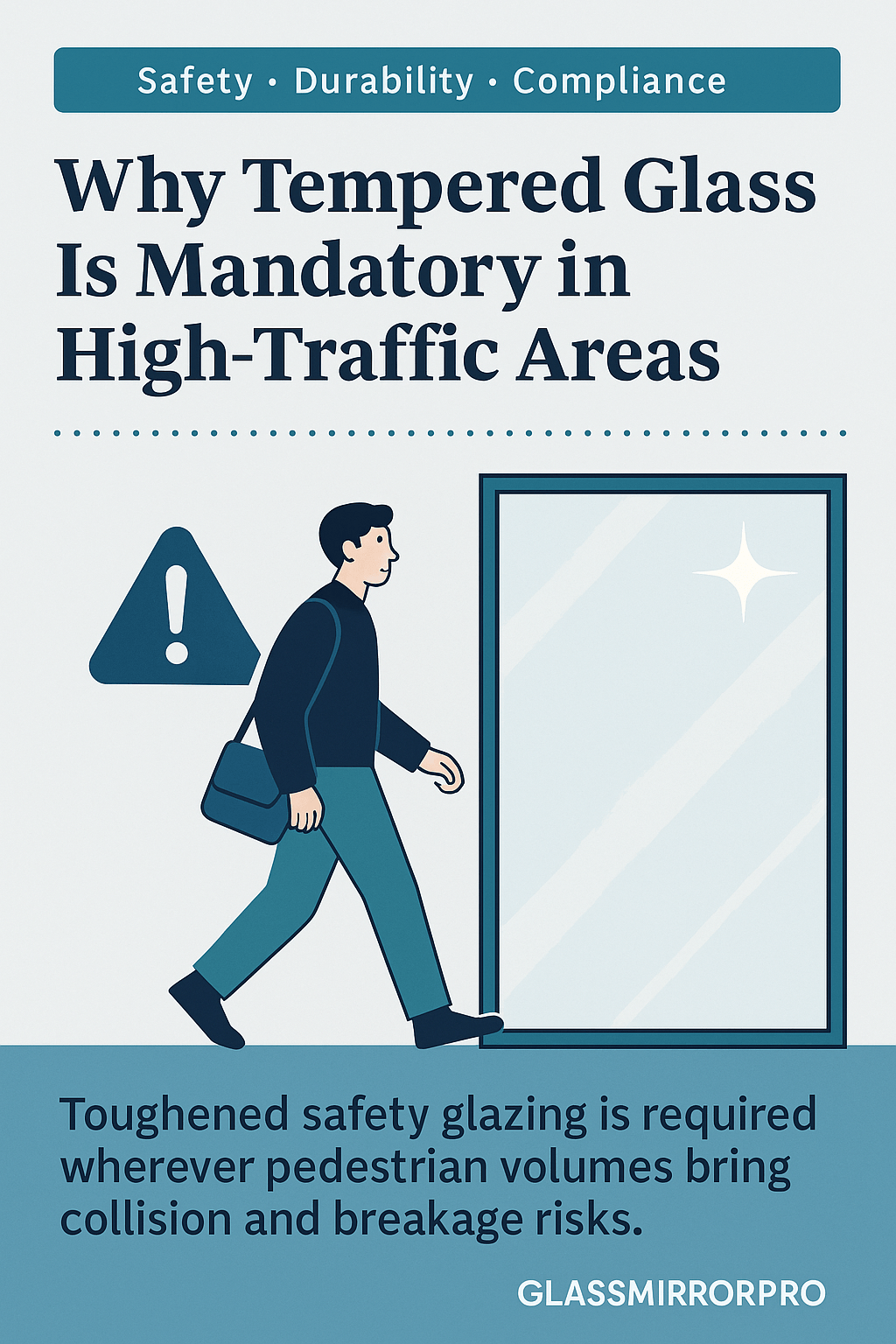

2. Wrong Glass Type for the Location

Installing standard (annealed) glass where tempered or laminated safety glass is required violates building codes. Always verify project zone requirements before ordering.

3. Missing Certification Marks

Many contractors overlook checking for etched marks like ANSI Z97.1 or CPSC 16 CFR 1201 on the glass pane. Without them, the glass may never pass inspection.

4. Incorrect Glazing Size Allowance

Glass expands and contracts with temperature. Failing to leave proper clearances (especially on large panels) causes pressure and eventual breakage.

5. Poor Frame Compatibility

Using rigid metallic frames without proper gaskets or supports can stress glass edges. Always design frames that allow slight movements and use edge cushioning.

6. Neglecting Manifestation Requirements

Clear glass panels must include visible markings (frosted lines, decals) at eye/waist height to prevent people walking into them — especially in offices or corridors.

7. Unsafe Handling on Site

Lack of PPE, inadequate training, or dropping panels can cause micro-cracks. Always use suction cups, gloves, and multiple handlers for large panels.

8. Ignoring Building Code 2406

Some glazing installations fall under IBC Section 2406 (required safety glazing zones). Installing non-rated glass in these zones risks non-compliance and liabilities.

9. Wrong Sealants or Adhesives

Incompatible chemicals or expansions in adhesives may delaminate or degrade glass over time. Always use manufacturer-recommended sealants tested for glazing use.

10. Skipping Final Safety Inspection

Without a final check of all panels, markings, and hardware, mistakes go uncorrected. Always walk-through your install before sign-off.

Further Reading

For additional context on safety glazing specifications and performance criteria, check out

this resource on GlassHelp.

Leave a comment